Engineering, 16.12.2020 02:30 dianamachado14

**figure screen shot attached**

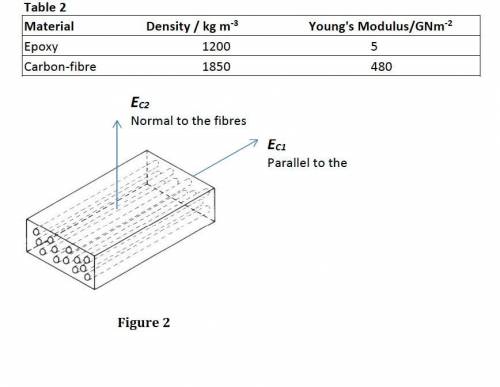

A composite component (such as shown in Fig.2) is required for an aerospace application. The specification for the component stipulates that it must have an Elastic Modulus in the fibre direction of at least 320 GN/m2, and the transverse direction modulus must not be less than 8 GN/m2, but with a maximum permissible density of 1650 kg/m3. In order to determine if such a composite is possible:

i) Plot (preferably using excel), the composite modulus (Ec) versus fibre volume fraction (Vf) showing upper (isostrain model – parallel to the fibres) and lower (isostress model - perpendicular to the fibres) bounds for the Epoxy/Carbon-fibre composite (data are provided in Table 2);

ii) Estimate the carbon fibre volume fraction required to achieve the above specification.

(Hint from the plot in part i) find the Vf for the required modulus [320 GPa] in the fibre direction – upper bound line, then check if the lower limit is okay, finally workout the density of the composite to see if it is within the spec – also check your answer with calculations)

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, ahmedeldyame

Aloaded platform of total mass 500 kg is supported by a dashpot and by a set of springs of effective stiffness 72 kn/m. it is observed that when the platform is depressed through a distance x = 12.5 cm below its equilibrium position and then released without any initial velocity; it reaches its equilibrium position in the shortest possible time without overshoot. find the position and velocity of the loaded platform 0.10 sec. after its release. if a further load of 400 kg is added to the platform, find, i) the frequency of damped vibrations, and i) the amplitude of vibration after 2 complete oscillations, given that the initial amplitude is 15 cm.

Answers: 1

Engineering, 04.07.2019 18:10, bckyanne3

Afull journal bearing has a journal diameter of 27 mm, with a unilateral tolerance of -0.028 mm. the bushing bore has a diameter of 27.028 mm and a unilateral tolerance of 0.04 mm. the l/d ratio is 0.5. the load is 1.3 kn and the journal runs at 1200 rev/min. if the average viscosity is 50 mpa-s, find the minimum film thickness, the power loss, and the side flow for the minimum clearance assembly.

Answers: 1

Engineering, 04.07.2019 18:10, michellerosas

Ajournal bearing has a journal diameter of 3.250 in with a unilateral tolerance of 20.003 in. the bushing bore has a diameter of 3.256 in and a unilateral tolerance of 0.004 in. the bushing is 2.8 in long and supports a 700-lbf load. the journal speed is 900 rev/min. find the minimum oil film thickness and the maximum film pressure for both sae 20 and sae 20w-30 lubricants, for the tightest assembly if the operating film temperature is 160°f. a computer code is appropriate for solving this problem.

Answers: 3

Engineering, 04.07.2019 18:10, oliviasoreo92

Compute the pressure drop of 30°c air flowing with a mean velocity of 8 m/s in a circular sheet-metal duct 300 mm in diameter and 15 m long. use a friction factor, f 0.02, and pair = 1.1644 kg/m a. 37.26 pa b. 25.27 pa n c. 29.34 pa d. 30.52 pa

Answers: 1

You know the right answer?

**figure screen shot attached**

A composite component (such as shown in Fig.2) is required for an a...

Questions in other subjects:

Mathematics, 14.06.2020 04:57

English, 14.06.2020 04:57

Mathematics, 14.06.2020 04:57