Engineering, 15.07.2020 02:01 Tatertotzzzz

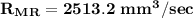

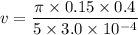

In a production turning operation, an engineer wants a single pass must be completed on the cylindrical workpiece in 5.0 min. The piece is 400 mm long and 150 mm in diameter. Using a feed = 0.30 mm/rev and a depth of cut = 4.0 mm, what cutting speed must be used to meet this machining time requirement? Also calculate the material removal rate for this operation in cubic mm/seconds.

Answers: 2

Other questions on the subject: Engineering

Engineering, 06.07.2019 04:10, idjfjcjs584

Along steel shaft of 10 cm diameter is austenised at 870°c and then quenched in a liquid at 30oc. the average surface heat transfer coefficient is 2000 w/m2. °c. the relevant thermophysical properties of the shaft are: p=7800 kg/m", k=20 w/mk, cp=0.46 kj/kg. k calculate: a)-the time required for the center temperature to drop to 200°c. b)-the temperature at half-radius at that moment. c)-the amount of heat that had been transferred to the liquid by that time per meter length of the shaft

Answers: 1

You know the right answer?

In a production turning operation, an engineer wants a single pass must be completed on the cylindri...

Questions in other subjects:

English, 21.04.2020 23:50

Mathematics, 21.04.2020 23:50

m/rev

m/rev

= time

= time Diameter

Diameter

for this operation is :

for this operation is :