Engineering, 30.03.2020 19:13 ella8586

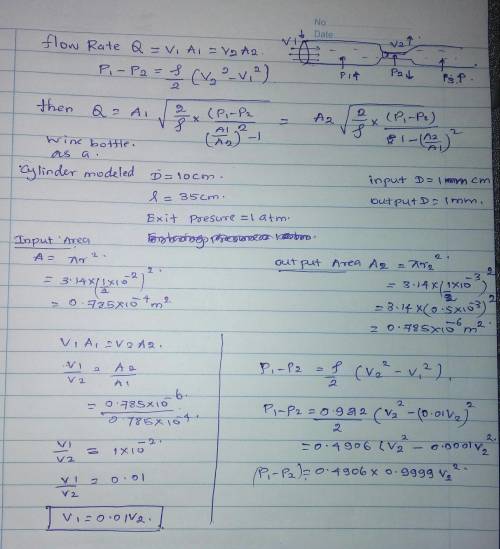

A wine aerator is a small, in-bottle, hand-held pour-through or decantor top device using the venturi effect for aerating the wine. These devices mix air into the wine as it flows through (or over), increasing exposure to oxygen and causing aeration. Apparently, wine which has been aerated tastes better. You want to design a new aerator that will also chill the wine as it is poured. This aerator will be aventuri-shaped tube with an input diameter of 1 cm and an output diameter of 1 mm. Determine the flow rate of the wine exiting theventure tube while pouring as a function of pouring angle and volume of wine in the bottle. The wine bottle can be modeled as a cylinder of 10 cm in diameter and length of 35 cm. You can assume the pressure at the exit is 1 atm and you can assume the head in the bottle while pouring has a pressure of 1 atm. You will need to determine the pressure at the inlet of the aerator as a function of time at various angles. Assume the bottle starts full. Also, calculate the resultant force needed to keep the device attached to the top of your wine bottle as a function of time for the same angles. Comment on maximum forces. Finally, you need to determine the rate that energy needs to be removed to chill the wine from room temperature to 4 C as it flows through the aerator.

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, lillygrl100

For the closed feedwater heater below, feedwater enters state 3 at a pressure of 2000 psia and temperature of 420 °f at a rate of ix10 ibhr. the feedwat extracted steam enters state 1 at a pressure of 1000 psia and enthalpy of 1500 btu/lbm. the extracted er leaves at an enthalpy of 528.7 btu/lbm steam leaves as a saturated liquid. (16) a) determine the mass flow rate of the extraction steam used to heat the feedwater (10) b) determine the terminal temperature difference of the closed feedwater heater

Answers: 3

Engineering, 04.07.2019 18:20, cxttiemsp021

Atank with constant volume contains 2.27 kg of a mixture of water phases (liquid-vapor). in the initial state the temperature and the quality are 127 °c and 0.6, respectively. the mixture is heated until the temperature of 160 oc is reached. illustrate the process in a t-v diagram. then, determine (1) the mass of the vapor in kg at the initial state, (2) the final pressure in kpa.

Answers: 3

Engineering, 04.07.2019 18:20, Doogsterr

For each of the following process: a) sketch the p-v diagram, b)sketch t-s diagram, c) sketch t-v diagram, d) sketch the boundary work on one of the diagrams (a, b or c) and e) sketch the reversible heat transfer on one of the diagrams (a, b or c): 1- isobaric process from compressed liquid to superheated vapor 2- isothermal process from compressed liquid to superheated vapor 3- isentropic process from compressed liquid to superheated vapor

Answers: 3

Engineering, 04.07.2019 19:10, santosbeti90

With increases in magnification, which of the following occur? a. the field of view decreases. b. the ambient illumination decreases. c. the larger parts can be measured. d. the eyepiece must be raised.

Answers: 1

You know the right answer?

A wine aerator is a small, in-bottle, hand-held pour-through or decantor top device using the ventur...

Questions in other subjects:

Computers and Technology, 18.02.2021 05:00

Mathematics, 18.02.2021 05:00

Law, 18.02.2021 05:00

Biology, 18.02.2021 05:00