Engineering, 28.03.2020 04:41 jose477

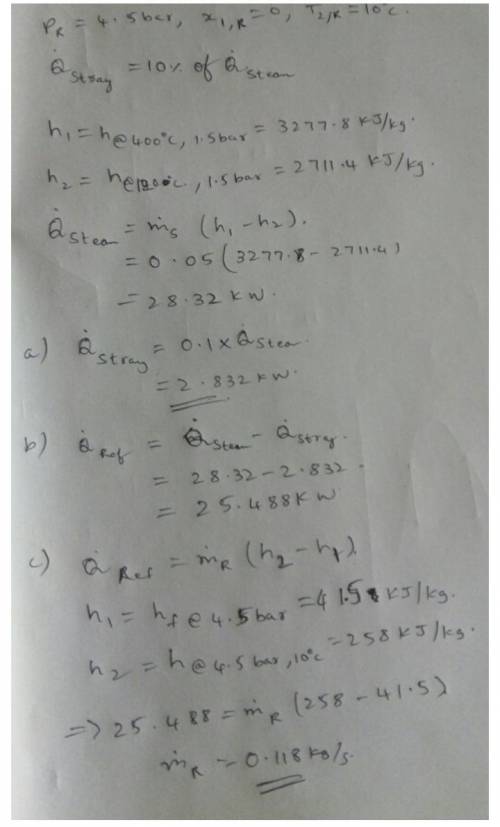

Steam enters a heat exchanger at a pressure of 1.5 bar and a temperature of 400°C with a mass flow rate of 0.05 kg/s and exits at a temperature of 120°C and at the same inlet pressure. The steam heat transfer takes place with refrigerant R22 in a separate stream. The refrigerant enters the heat exchanger as liquid at 4.5 bar and leaves at the same pressure and at a temperature of 10°C. The heat exchanger is not well designed and there is stray heat transfer to the surroundings equal to 10% of the heat transferred from the steam.

Determine

(a) The rate of stray heat transfer, in kW.

(b) The rate of heat transfer to the refrigerant, in kW

(c) The mass flow rate of the refrigerant, in kg/s

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:10, niyawilliams23

Asingle-geared blanking press has a stroke of 200 mm and a rated capacity of 320 kn. a cam driven ram is assumed to be capable of delivering the full press load at constant force during the last 15 percent of a constant-velocity stroke. the camshaft has an average speed of 90 rev/min and is geared to the flywheel shaft at a 6: 1 ratio. the total work done is to include an allowance of 16 percent for friction a) estimate the maximum energy fluctuation b) find the rim weight for an effective diameter of 1.2 m and a coefficient of speed fluctuation of 0.10

Answers: 1

Engineering, 04.07.2019 18:20, maciemarklin79981

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

Engineering, 04.07.2019 18:20, 21megoplin

How much power could a wind turbine produce if it had the following specifications? cp = 0.45 -d=1.2kg/m3 d=50m v 5m/s

Answers: 2

You know the right answer?

Steam enters a heat exchanger at a pressure of 1.5 bar and a temperature of 400°C with a mass flow r...

Questions in other subjects:

Advanced Placement (AP), 20.09.2021 22:20

Biology, 20.09.2021 22:20

Mathematics, 20.09.2021 22:20

Mathematics, 20.09.2021 22:20