Engineering, 24.03.2020 18:01 hellokitty1647

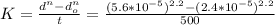

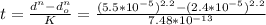

A hypothetical metal alloy has a grain diameter of 2.4 × 10−2 mm. After a heat treatment at 575°C for 500 min, the grain diameter has increased to 5.6 × 10−2 mm. Compute the time required for a specimen of this same material (i. e., d0 = 2.4 × 10−2 mm) to achieve a grain diameter of 5.5 × 10−2 mm while being heated at 575°C. Assume the n grain diameter exponent has a value of 2.2.

Answers: 2

Other questions on the subject: Engineering

Engineering, 03.07.2019 14:10, cowgyrlup124

Explain the difference laminar and turbulent flow. explain it with the shear stress and the velocity profiles.

Answers: 1

Engineering, 04.07.2019 18:10, keigleyhannah30

Aplate clutch has a single pair of mating friction surfaces 250-mm od by 175-mm id. the mean value of the coefficient of friction is 0.30, and the actuating force is 4 kn. a) find the maximum pressure and the torque capacity using the uniform-wear model. b) find the maximum pressure and the torque capacity using the uniform-pressure model.

Answers: 3

Engineering, 04.07.2019 18:10, qwertylol12345

Different types of steels contain different elements that alter the characteristics of the steel. for each of the following elements, explain what the element does when alloyed with steel.

Answers: 2

Engineering, 04.07.2019 18:10, xboxdude06

Slip occurs via two partial dislocations because of (a) the shorter path of the partial dislocation lines; (b) the lower energy state through partial dislocations; (c) the charge balance.

Answers: 1

You know the right answer?

A hypothetical metal alloy has a grain diameter of 2.4 × 10−2 mm. After a heat treatment at 575°C fo...

Questions in other subjects:

Mathematics, 25.03.2021 20:00

Mathematics, 25.03.2021 20:00

Mathematics, 25.03.2021 20:00

Mathematics, 25.03.2021 20:00

English, 25.03.2021 20:00

Biology, 25.03.2021 20:00

Biology, 25.03.2021 20:00

= 7.48 × 10⁻¹³ m/min

= 7.48 × 10⁻¹³ m/min = 477 min

= 477 min