Engineering, 06.03.2020 19:53 marcos86

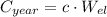

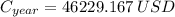

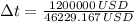

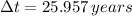

An investor is to install a total of 40 identical wind turbines in a location with an average wind speed of 7.2 m/s. The blade diameter of each turbine is 18 m and the average overall wind turbine 5-28 efficiency is 33 percent. The turbines are expected to operate under these average conditions 6000 h per year and the electricity is to be sold to local utility at a price of $0.075/kWh. If the total cost of this installation is $1,200,000, determine how long it will take for these turbines to pay for themselves. Take the density of air to be 1.18 kg/m

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 18:20, krojas015

Asolid cylinder is concentric with a straight pipe. the cylinder is 0.5 m long and has an outside diameter of 8 cm. the pipe has an inside diameter of 8.5 cm. the annulus between the cylinder ad the pipe contains stationary oil. the oil has a specific gravity of 0.92 and a kinematic viscosity of 5.57 x 10-4 m2/s. most nearly, what is the force needed to move the cylinder along the pipe at a constant velocity of 1 m/s?

Answers: 3

Engineering, 04.07.2019 19:20, mercedesamatap21hx0

To design a steam turbine to produce 12,000 hp power. a engineer comsiders using a steady state stean low st 1160fr and engineer considers using a steady state steam flow at 1160°r and 450 psia to drive this steam turbine. the exhaust of the steam is cooled by the lake (vacuum). heat losing to the surroundings is measured at a rate of 555.55 btu/s. (a) sketch the system with the given conditions. (b) neglecting kinetic and potential energy changes from inlet to exit, determine the volumetric flow rate of the steam at the inlet, (ft'/hr). must clearly show unit conversions at crtical terms.

Answers: 1

Engineering, 04.07.2019 19:20, kaitlyn114433

Ashielded metal arc-welding operation is accomplished in a work cell by a fitter and a welder. the fitter takes 5.5 min to load components into the welding fixture at the beginning of the work cycle, and 1.5 min to unload the completed weldment at the end of the cycle. the total ength of the weld seams 1200 mm, and the travel speed used by the welder averages 300 mm/min. every 600 mm of seam length, the welding stick must be changed, which takes 0.8 min. while the fitter is working, the welder is idle (resting): and while the welder is working the fitter is idle. (a) determine the average arc-on time as a fraction of the work cycle time. (b) how much improvement in arc-on time would result if the welder used flux-cored arc welding (manually operated), given that the spool of weld wire must be changed every 10 weldments, and it takes the welder 5.0 min to accomplish the change? (c) what are the production rates for these two cases (weldments completed per hour)? attach your work and solutions.

Answers: 1

Engineering, 06.07.2019 03:20, s6ties

1kg of water contained in a piston-cylinder assembly undergoes two processes in series from an initial state where the pressure is 3.0 bar and the temperature is 150°c process 1-2: the water is compressed isothermally to a volume of 0.25 m^3 with 120 kj of work being done to the system. process 2-3: the water is heated at constant volume to a final pressure of 10 bar. a. find the change in internal energy for the system. b. calculate the amount of heat transferred, in kj. c. sketch both processes on a t-v diagram. (196.33 kj/kg, 76.33 kj)

Answers: 1

You know the right answer?

An investor is to install a total of 40 identical wind turbines in a location with an average wind s...

Questions in other subjects:

Mathematics, 16.12.2020 06:30

Arts, 16.12.2020 06:30

Mathematics, 16.12.2020 06:30

Chemistry, 16.12.2020 06:30

![W_{el} = (0.33)\cdot (40) \cdot \frac{1}{2} \cdot (1.18\,\frac{kg}{m^{3}})\cdot [\frac{\pi}{4}\cdot (18\,m)^{2}}] \cdot (7.2\,\frac{m}{s} )^{2}\cdot (6000\,h)\cdot (\frac{3600\,s}{1\,h} )](/tpl/images/0535/8917/51355.png)