Engineering, 31.10.2019 01:31 odelancy14

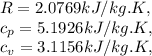

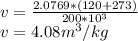

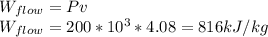

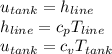

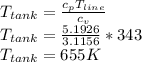

Arigid, insulated tank that is initially evacuated is connected through a valve to a supply line that carries helium at 200 kpa and 120°c. now the valve is opened, and helium is allowed to flow into the tank until the pressure reaches 200 kpa, at which point the valve is closed. determine the flow work of the helium in the supply line and the final temperature of the helium in the tank.

Answers: 3

Other questions on the subject: Engineering

Engineering, 04.07.2019 19:10, Lexi5170

A)-explain briefly the importance of standards in engineering design. b)- what is patent? c)-explain the relationship between these standards: b. s. and b. s.en d)- in engineering design concepts, types of loads and how they act are important factors. explain.

Answers: 3

Engineering, 04.07.2019 19:20, Katmcfee7681

Acommercial grade cubical freezer, 4 m on a side, has a composite wall consisting of an exterior sheet of 5.0-mm thick plain carbon steel (kst= 60.5 w/m k), an intermediate layer of 100-mm thick polyurethane insulation (kins 0.02 w/m k), and an inner sheet of 5.0- mm thick aluminium alloy (kal polyurethane insulation and both metallic sheets are each characterized by a thermal contact resistance of r 2.5 x 104 m2 k/w. (a) what is the steady-state cooling load that must be maintained by the refrigerator under conditions for which the outer and inner surface temperatures are 25°c and -5°c, respectively? (b) for power saving purpose, which wall material should be increased/reduced in. thickness in order to reduce 50% of the cooling load found in part (a)? redesign the thickness of the proposed material. 177 w/m-k). adhesive interfaces between the q=575.93 w

Answers: 2

Engineering, 06.07.2019 02:30, sandy2597

Precipitation hardening can be achieved in many light alloys by a three-step heat treatment. what is carried out and what is the purpose at each step? why is such a treatment necessary based on the nucleation and growth theory of phase transformation. compare this treatment with tempering martensite for carbon steels (similarities and differences).

Answers: 1

Engineering, 06.07.2019 03:10, tatedason33741

Asolid steel sphere (k=63.9 w m-1 k-1 , ? =7832 kg m-3 , c=0.523 kj kg-1 k-1 ), 100 mm in diameter is initially at a uniform temperature of 500o c and is suddenly quenched in a large oil bath for which t? = 100o c and h = 3200 w m-2 k-1. estimate the time required for the sphere to cool to 200o c and to 110o c

Answers: 1

You know the right answer?

Arigid, insulated tank that is initially evacuated is connected through a valve to a supply line tha...

Questions in other subjects:

English, 02.12.2020 21:30

Physics, 02.12.2020 21:30

Mathematics, 02.12.2020 21:30