Engineering, 05.10.2019 10:00 AutumnJoy12

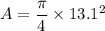

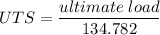

A356 cast aluminum test bar is tested in tension. the initial gage length as marked on the sample is 50mm and the initial diameter is 13.1mm. after fracture, the gage length is 53.7mm and the final diameter is 12.6mm. what is the uts?

Answers: 1

Other questions on the subject: Engineering

Engineering, 04.07.2019 03:10, lauriepdx17

What precautions should you take to prevent injuries when dealing with heavy loads?

Answers: 1

Engineering, 04.07.2019 12:10, Ryantimes2

On a average work day more than work place firs are reorted

Answers: 1

Engineering, 04.07.2019 18:20, maciemarklin79981

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

You know the right answer?

A356 cast aluminum test bar is tested in tension. the initial gage length as marked on the sample is...

Questions in other subjects:

Mathematics, 03.11.2020 08:50

Biology, 03.11.2020 08:50

English, 03.11.2020 08:50

English, 03.11.2020 08:50

English, 03.11.2020 08:50

Social Studies, 03.11.2020 08:50

Chemistry, 03.11.2020 08:50