Engineering, 11.07.2019 02:20 milak23

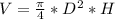

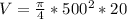

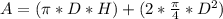

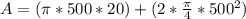

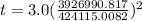

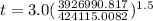

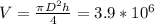

Adisk-shaped part is to be cast out of aluminum. the diameter 500 mm and thickness = 20 mm. if the mold constant = 3.0 s/mm2 in chvorinov's rule, how long will it take the casting to solidify, in minutes?

Answers: 2

Other questions on the subject: Engineering

Engineering, 04.07.2019 12:10, Ryantimes2

On a average work day more than work place firs are reorted

Answers: 1

Engineering, 04.07.2019 18:10, lerasteidl

Determine whether or not it is possible to compress air adiabatically from k to 140 kpa and 400 k. what is the entropy change during this process?

Answers: 3

Engineering, 04.07.2019 18:20, maciemarklin79981

A3-mm-thick panel of aluminum alloy (k 177 w/m-k, c 875 j/kg-k and ? = 2770 kg/m) is finished on both sides with an epoxy coating that must be cured at or above t,-150°c for at least 5 min. the production line for the curing operation involves two steps: (1) heating in a large oven with air at ts,0-175°c and a convection coefficient of h, 40 w/m2. k, and (2) cooling in a large chamber with air at 25°c and a con- vection coefficient of he 10 w/m2.k. the heating portion of the process is conducted over a time interval te which exceeds the ime required to reach 150°c by 5 min (h = r + 300 s). the coating has an emissivity of ? = 0.8, and the temperatures of the oven and chamber walls are 175 and 25°c, respectively. if the panel is placed in the oven at an initial temperature of 25°c and removed from the chamber at a safe-to-touch tempera ture of 37°c, what is the total elapsed time for the two-step curing operation?

Answers: 3

You know the right answer?

Adisk-shaped part is to be cast out of aluminum. the diameter 500 mm and thickness = 20 mm. if the m...

Questions in other subjects:

Mathematics, 04.07.2019 13:30

Mathematics, 04.07.2019 13:30

History, 04.07.2019 13:30

English, 04.07.2019 13:30

Advanced Placement (AP), 04.07.2019 13:30

mm3

mm3 mm2

mm2 mm

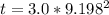

mm =253.8s

=253.8s