Business, 22.11.2019 06:31 gjvyverman

Tco case study distribution example 2015 version 1.2 you work for idc distributions llc.

you're responsible for sourcing new products. your company is launching a new product. you’ve found two possible sources – a domestic manufacturer and a manufacturer based on south korea. below are more details about each of the manufacturers.

domestic manufacturer

the domestic manufacturer, cornhusker industries (chi), is a qualified supplier. chi will produce a finished good in lincoln nebraska. from there, finished goods will be shipped via rail to your distribution center in dallas. it takes chi 10 days to make an order and then 5 days in transit to your warehouse. shipping costs are fob origin and cost $1,850 per teu (twenty-foot equivalent units). each teu can hold up to 600 units of your product. chi proposed a price of $85.00 per unit when responding to your request for proposal.

global supplier

the other possible supplier is kbm, which is a highly qualified supplier located just outside of seoul korea. kbm ships product via rail to the port of busan, which is located in mouth of the naktong river in south korea. it is the tenth biggest port in the world based on cargo throughput. when an order is placed with kbm it takes 15 days for kbm to manufacture the order and place the order in teus used for shipping. it takes one day for rail from seoul to busan. the shipment will wait 4 days in busan to be loaded on to a ship. from there it takes 16 days to cross the pacific ocean to the port of long beach, and then 3 additional days to clear customs. once the shipment clears customers, it is loaded on to rail and shipped fob origin. it arrives in dallas in 4 days. import tariffs and duties are $325 per teu. rail shipping costs are $2,250 from long beach to dallas. in the rfp, kbm’s bid was 85,477.37 korean won per unit (current exchange rate is $1=1,067 krw).

additional details

transport in the usa, whether from domestic or international suppliers, will travel via rail. the products will be in teus (twenty-foot equivalent units) for shipping and each teu can contain up to 600 units of your new product. your inventory carrying costs are 32.2%. also, each order placed costs $105 for domestic suppliers and $182 for international suppliers. the international ordering costs are higher due to the additional complexity of getting products through customs.

working with your heads of cost accounting and demand planning, you’ve done some preliminary calculations and have determined that: • safety stock required would be 432 units for the global supplier and 160 for the domestic manufacturer • average cycle stock inventory (the average non-safety stock inventory) would be 275.5 for the global supplier and 203.5 for the domestic supplier • annual demand for the new product is 21,500 units • the optimal number of orders (based on demand and eoq formula) for the global supplier is 39.2 and is 52.83 for the domestic supplier • ocean shipping costs from bosan are $1,818 per teu

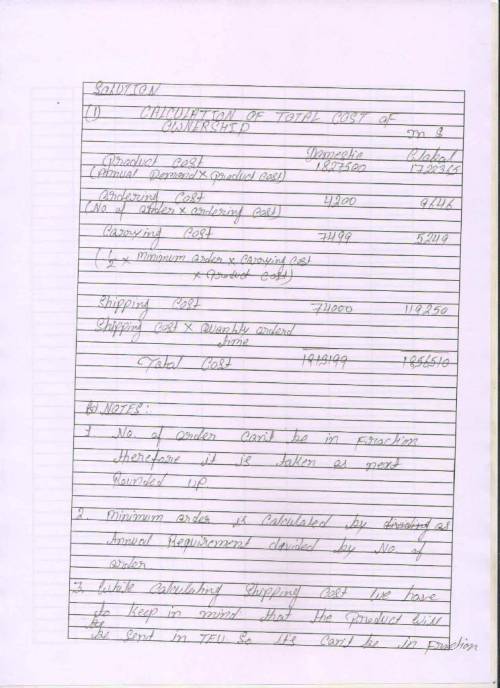

questions: (1) what is the total cost of ownership for each supplier? (2) which supplier would you choose and why?

Answers: 1

Other questions on the subject: Business

Business, 21.06.2019 22:30, tinasidell1972

Your project team’s recommendations to increase productivity have been approved and your team is now working on an implementation plan. in order to accomplish the plan, several subject matter experts from various parts of the organization have been brought in to assist. you have noticed friction and conflict among team members. some of the disagreement and opposition on your team supports the achievement of team goals and objectives. this type of conflict can be described as:

Answers: 1

Business, 21.06.2019 22:50, jonlandis6

Synovec co. is growing quickly. dividends are expected to grow at a rate of 24 percent for the next three years, with the growth rate falling off to a constant 7 percent thereafter. if the required return is 11 percent, and the company just paid a dividend of $2.05, what is the current share price? (do not round intermediate calculations and round your answer to 2 decimal places, e. g., 32.16.)

Answers: 2

Business, 22.06.2019 06:40, lexhorton2002

Burke enterprises is considering a machine costing $30 billion that will result in initial after-tax cash savings of $3.7 billion at the end of the first year, and these savings will grow at a rate of 2 percent per year for 11 years. after 11 years, the company can sell the parts for $5 billion. burke has a target debt/equity ratio of 1.2, a beta of 1.79. you estimate that the return on the market is 7.5% and t-bills are currently yielding 2.5%. burke has two issuances of bonds outstanding. the first has 200,000 bonds trading at 98% of par, with coupons of 5%, face of $1000, and maturity of 5 years. the second has 500,000 bonds trading at par, with coupons of 7.5%, face of $1000, and maturity of 12 years. kate, the ceo, usually applies an adjustment factor to the discount rate of +2 for such highly innovative projects. should the company take on the project?

Answers: 1

Business, 22.06.2019 14:00, lindjyzeph

The following costs were incurred in may: direct materials $ 44,800 direct labor $ 29,000 manufacturing overhead $ 29,300 selling expenses $ 26,800 administrative expenses $ 37,100 conversion costs during the month totaled:

Answers: 2

You know the right answer?

Tco case study distribution example 2015 version 1.2 you work for idc distributions llc.

...

...

Questions in other subjects:

Mathematics, 03.09.2020 01:01

History, 03.09.2020 01:01

Biology, 03.09.2020 01:01

Mathematics, 03.09.2020 01:01

Mathematics, 03.09.2020 01:01